Corrugated Metal Pipe (CMP) is fabricated from coils of galvanized steel. It can be manufactured in a wide range of shapes and sizes for a variety of uses. At Midwest Service and Sales, we stock CMP in diameters ranging from 6” up to 144”, with the option of riveted, spiral, or 5x1.

One of the most common questions our customers ask is, ‘What’s the difference between riveted and spiral pipe?’ The difference is in the way it is manufactured.

Riveted CMP is assembled by hand using cut-to-length sheets with annular 2-2/3”x1/2” corrugations. Longitudinal and circumferential lapped seams are fastened with rivets.

Riveted CMP

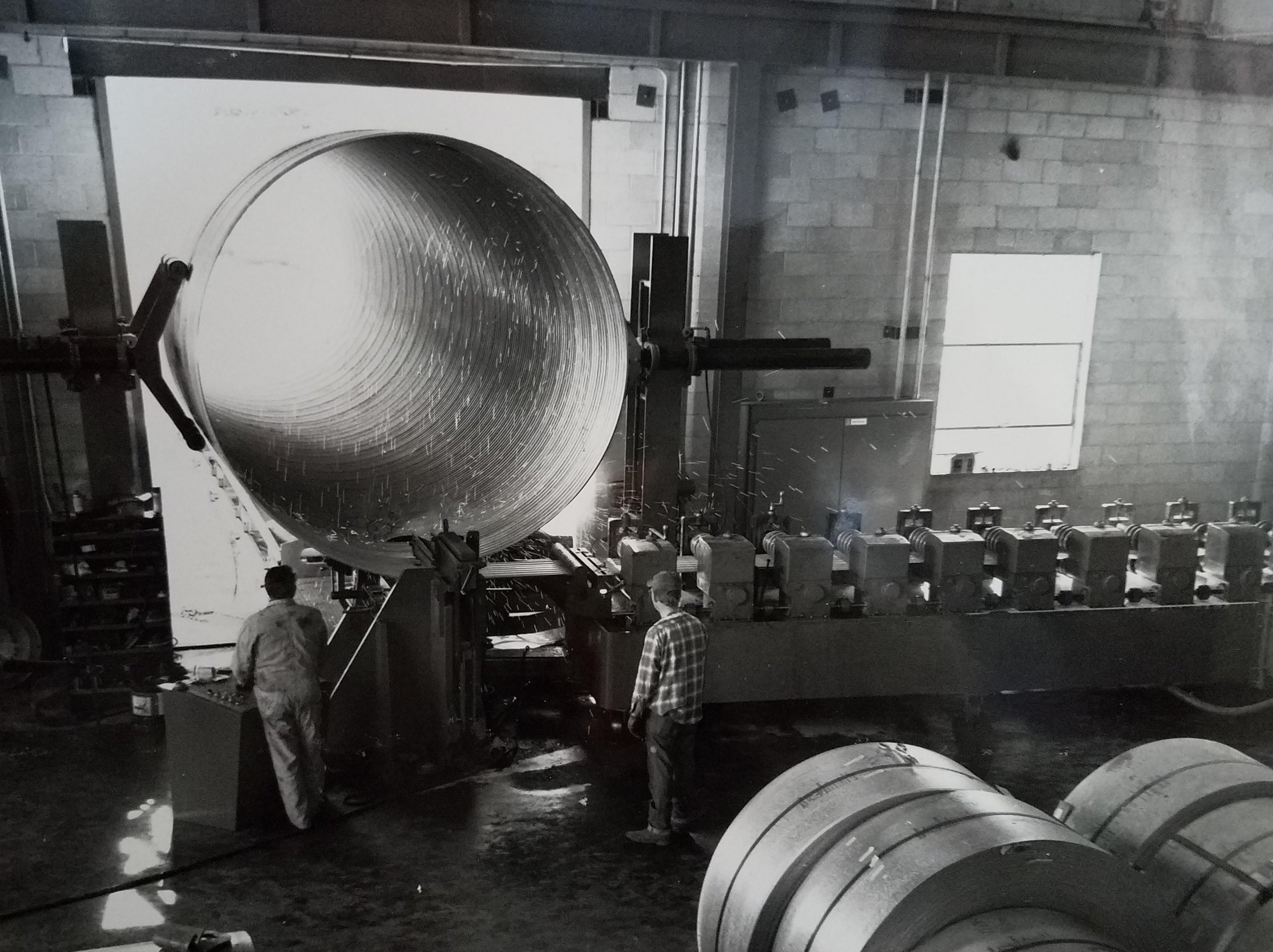

Spiral CMP is fabricated by machine using coiled steel sheet with helical 2-2/3”x1/2” corrugations and a continuous lock seam. The ends are rerolled annular. In diameters 60” and larger, we also offer 5x1 Spiral CMP. The wider pitch and 1” depth increases the strength of the corrugated steel, allowing for the use of a relatively lighter gauge of material for similar design considerations. 5x1 SCMP can reduce both the cost and the weight of the project.

Spiral CMP

In diameters 60” and larger, we also offer 5x1 Spiral CMP. The wider pitch and 1” depth increases the strength of the corrugated steel, allowing for the use of a relatively lighter gauge of material for similar design considerations. 5x1 SCMP can reduce both the cost and the weight of the project.

Since there is manual labor involved in manufacturing Riveted CMP, the cost is slightly higher than the same diameter and gauge of Spiral CMP. In a 1965 comparative study published by Ohio State University in Columbia, their principle conclusion is the welded, riveted, and 2-2/3 pitch spiral pipe specimens were, for all practical purposes, equal.

Culvert manufacturing plant, True North Steel, Huron, South Dakota.